Condensate Drain – JORC

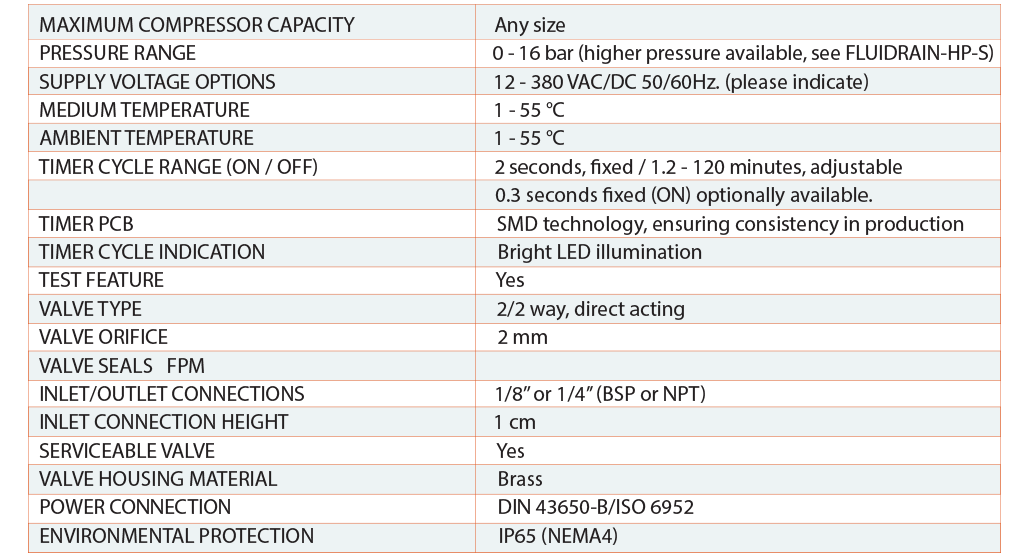

TIMER DRAIN – TEC 11

Timer drain for filters and dental compressors.

The TEC-11 Timer Controlled Condensate Drain is a combination of a solenoid valve and an electronic timer designed to automatically remove condensate from compressed air filters and small dental (oil free type) compressors.

The TEC-11 Timer Controlled Condensate Drain is a combination of a solenoid valve and an electronic timer designed to automatically remove condensate from compressed air filters and small dental (oil free type) compressors.

The clever in-line design allows for perfect installation under all types of compressed air filters and dental compressors, regardless of their capacity or size.

SPECIFICATIONS

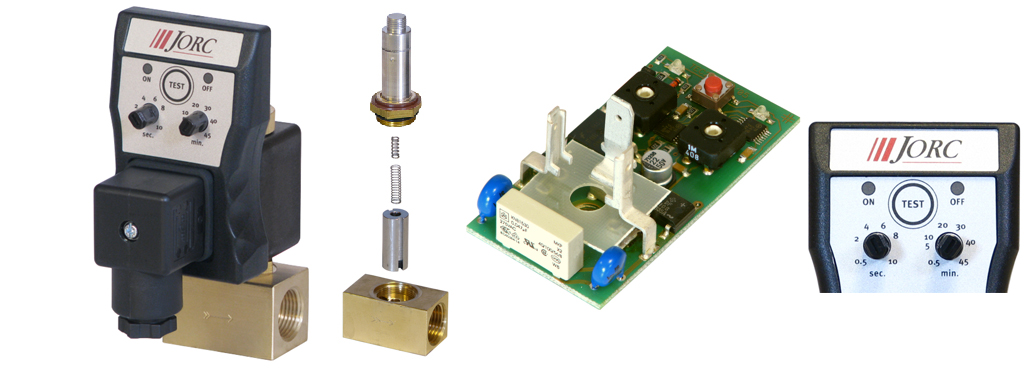

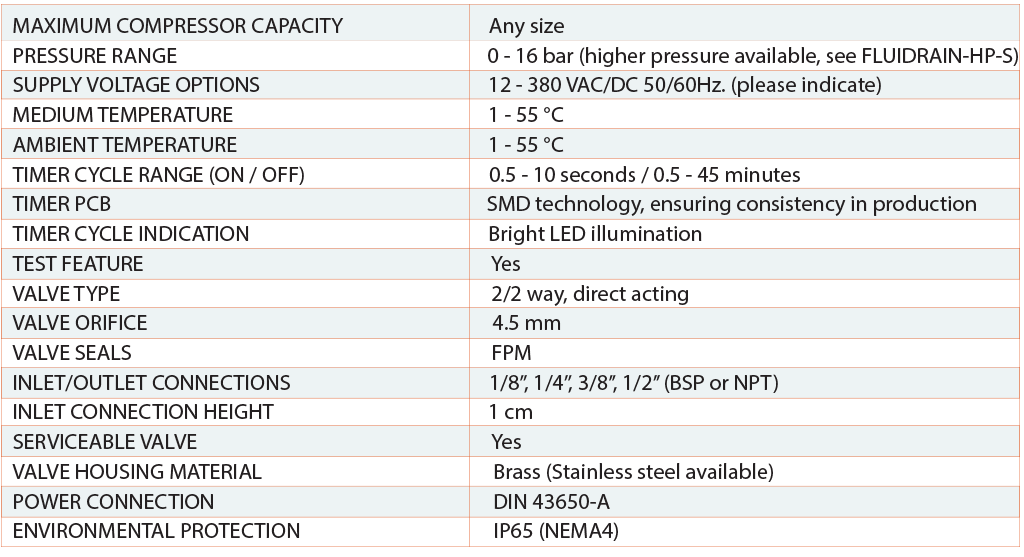

TIMER DRAIN – FLUIDRAIN

Electronic timer drain

The FLUIDRAIN Timer Controlled Condensate Drain is a combination of a solenoid valve and an electronic timer designed to automatically remove condensate from compressed air systems.

The FLUIDRAIN Timer Controlled Condensate Drain is a combination of a solenoid valve and an electronic timer designed to automatically remove condensate from compressed air systems.

The FLUIDRAIN is designed to remove condensate from compressors, compressed air dryers and receivers up to any size, type or manufacturer.

The FLUIDRAIN offers true installation simplicity and it is recognised as the most reliable and best performing condensate drain worldwide. The large orifice in the direct acting valve, combined with its sophisticated timer module ensure many years of trouble-free draining of condensate providing minimum service work is carried out.

SPECIFICATIONS

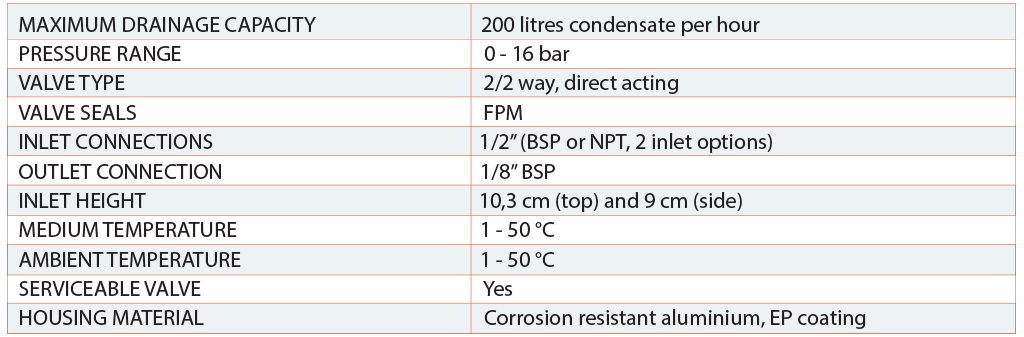

LEVEL SENSED DRAIN – MAGY

Magnetically operated zero air loss drain

The MAGY is a magnetically operated level sensed drain that discharges condensate from all compressed air systems by using a unique technology based on magnetic forces. The MAGY uses specially selected magnets that operate the 2/2 way direct acting valve assembly.

The discharge process of the MAGY is automatic and there is no loss of compressed air during the condensate discharge cycle.

The specially selected long-life magnets ensure a high operation consistency.

The MAGY is easy to install and to service due to the top and side inlet options. The MAGY is ideally suited in applications where power is not available, too expensive or not reliable.

Typically the MAGY is installed in refrigerated dryers and under piston compressors.

SPECIFICATIONS

LEVEL SENSED DRAIN – NUFORS CS

Pneumatically operated level sensed condensate drain

The NUFORS-CR removes condensate from compressed air systems without using electricity.

The discharge process is automatic and is based on a newly developed 3/2 way level controlled valve principle that operates a piston type direct acting valve. The advantage of this valve principle is that the NUFORS-CR’s orifice can be 6 mm, offering an increased reliability factor.

The NUFORS-CR is ideally suited in applications where power is not available, too expensive or not reliable.

In addition, the NUFORS-CR can be applied in applications that demand a higher IP rating (International Protection rating or Ingresss Protection.

The NUFORS-CR offers an IP 68/NEMA 6 rating.

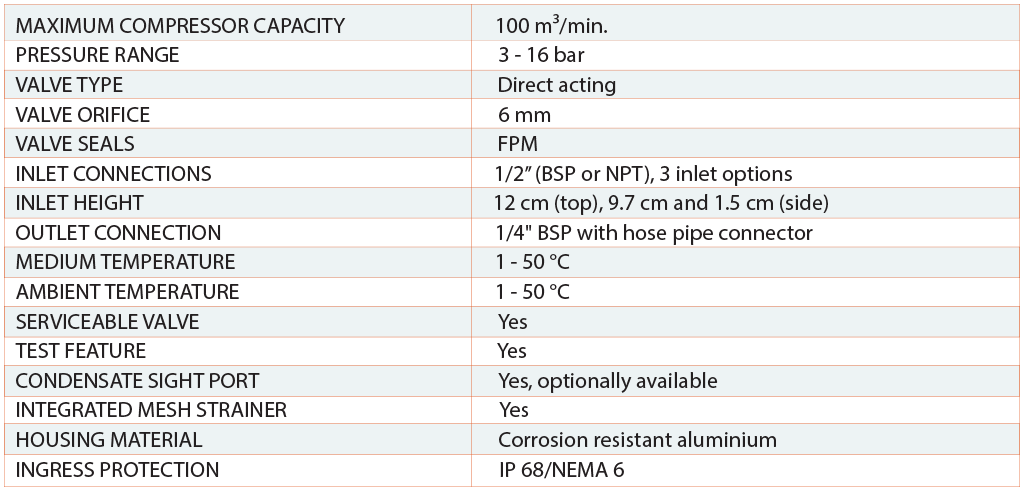

SPECIFICATIONS

LEVEL SENSED DRAIN – KAPTIV

Electronic zero air loss drain

The KAPTIV-CS (Compact Solution) removes all types of condensate from compressed air systems up to 100 m³/min. without the loss of compressed air.

The KAPTIV-CS (Compact Solution) removes all types of condensate from compressed air systems up to 100 m³/min. without the loss of compressed air.

The KAPTIV-CS is cost effective and offers a rapid pay-back period due to a competitive pricing level, low stocking cost, zero air-loss and energy saving features.

The compact robust industrial housing, 2/2 way direct acting valve with a large orifice, alarm NC or NO and the integrated mesh strainer make the KAPTIV-CS a highly reliable draining solution.

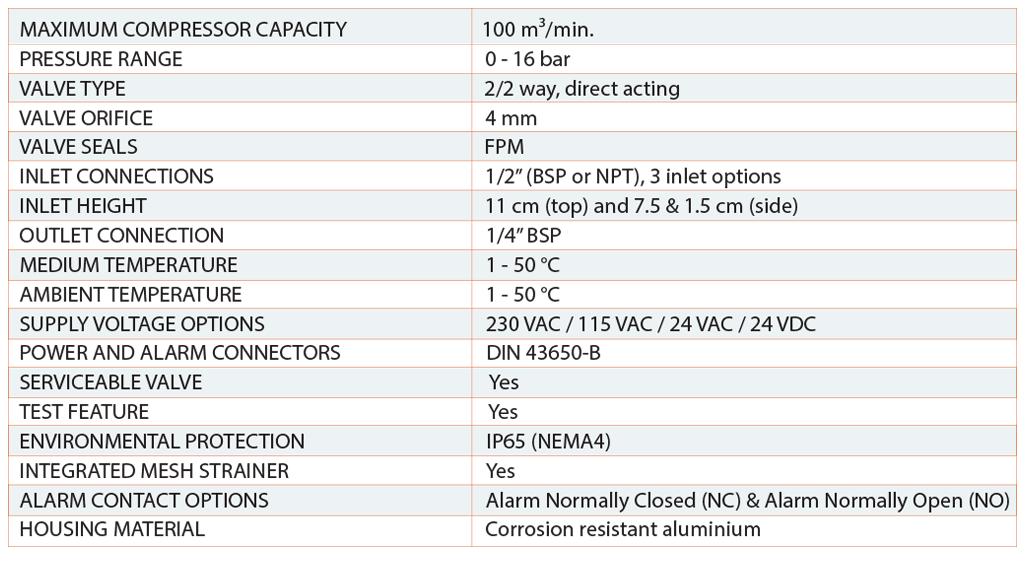

SPECIFICATIONS

TIMER DRAIN – TEC44

Unblockable motorised ball valve drain

The TEC-44 is a microprocessor operated ball valve, designed to remove condensate from deliquescent dryers, rusty old tanks, vessels and refrigerated dryers.

The TEC-44 is a powerful timer controlled motorized ball valve, designed to remove condensate from deliquescent dryers, tanks, vessels and refrigerated dryers.

The TEC-44 is designed to remove heavy contaminated condensate up to pressure ratings of 40 bar. This condensate drain can not be blocked and is applied where all else fails. Draining applications with a high level of contamination (rust, scale etc.) require the TEC-44.

The TEC-44 is impossible to block due to its powerful ball valve rotation and large orifice.

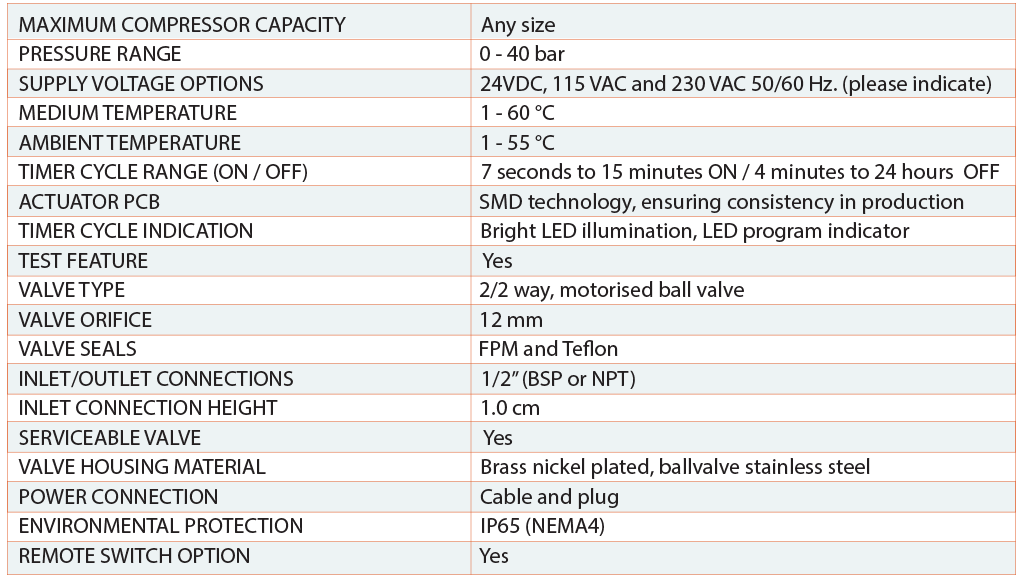

SPECIFICATIONS

ติดต่อเรา

บริษัท ก้าวหน้า อินดัสทรีส์ แอนด์ เอ็นจิเนียริ่ง จำกัด

55/17 หมู่ 4 ต. บึงคำพร้อย อ. ลำลูกกา จ.ปทุมธานี 12150

02-159-9861-4

02-159-9860

info@kaowna.co.th

Line ID : @kaowna

ติดตามข่าวสาร

Copyright © 2016 by Kaowna Industry & Engineering Co.,Ltd. – All Rights Reserved