SUTO-iTEC

S401 Flow Sensor Features

Features

• Tube diameters of DN25 to DN500.

• 2 installation types: center installation and 100 mm insertion depth installation for bigger pipes (> DN250)

• Installation under pressure through 1/2” ball valve

S430 Flow Sensor

S430 is based on the pitot tube principle to measure flow. Properly installed (refer to instruction manual for details) the sensor can measure in wet and dirty gases as occurring, for example, at the discharge of a compressor.

The sensor features long term stability , wide turn-down ratio and good temperature stability. It can be used in compressed air and non-corrosive gases.

Through a 1/2” G-type ball valve the sensor can be inserted into the pipe under pressure.

Various output signals allow the sensor to be connected to SUTO displays and/or third party displays and PLCs.

Application

S 430 measures:

– Standard flow and consumption

– Actual velocity

– Pressure

– Temperature

Features

• Flow and consumption measurement in wet air or high mass flow / velocity applications

• Measurement at compressor outlet

• Tube diameters of 1’’ to 10” through center installation, bigger diameters through non-center installation

• Insertion type, easy installation under pressure through ball valve possible

• High temperature applications up to 200 °C

• No mechanical wear parts

• All parts which are in contact with flow medium are made of stainless steel

• Compressor-FAD-Measurement

• Steam mass flow and consumption measurement

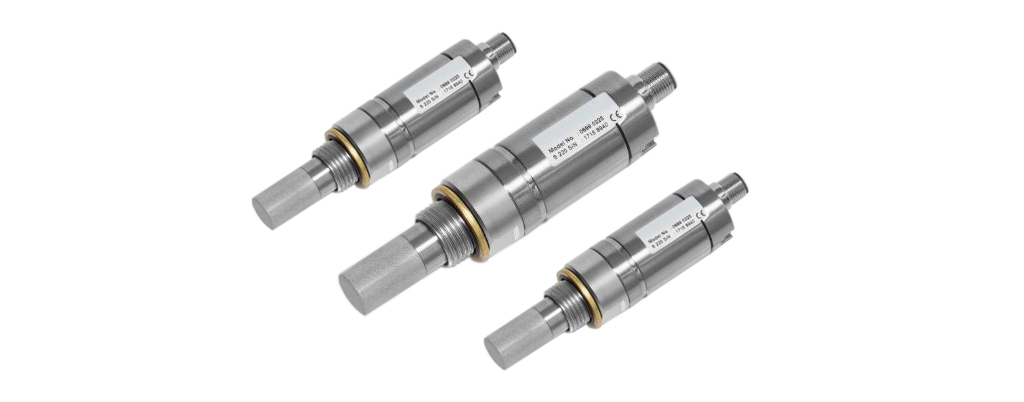

S 220 Dew Point Sensor

The SUTO dew point sensor S 220 provides reliable and long term stable dew point monitoring in industrial applications. SUTO is using a new sensor technology which has superior signals at very low moisture levels thus providing reliable measurements

down to -100 °C.

A stainless steel sinter filter with pore sizes below 30 μm protects the sensor from particles. It’s designed for applications where very low moisture levels needs to be detected.

The measured dew point is output through a 4-20 mA signal (3-wire or loop powered). Sensor parameters such as analogue output scaling, physical units, can be easily changed by using SUTO service kit.

Features

• Very fast response time ensures safe and reliable indication whenever dew points are out of valid ranges

• Small size makes it ideal for dryer installations

• Measures dew points down to -100 °C

• New SUTO sensor technology

• Version with integrated pressure measurement

• Various output versions available: 1 x 4 … 20 mA, 2 x 4 … 20 mA, RS-485 (Modbus), 4 … 20 mA loop powered

• IP 65 casing provides robust protection in rough industrial environment

• Can be installed directly into dryers through G 1/2” thread

• High accuracy of ± 2 °C dew point

• M12 connector

S460 Ultrasonic Flow Meter

Ultrasonic flow sensor/ meter S 460

The S 460 ultrasonic flow meter uses the proven clamp-on transit-time correlation technique. The ultrasonic transducers are simply clamped onto the outside of the pipe and never come in contact with the fluid.

The transducers are connected to a controller which is available as hat rail, or portable version. The stationary models can be connected to the S 330/331 series of displays and data loggers where the portable model is connectable to the S 551.

features

Measurement of liquid flows and consumption such as:

• Chemical addition

• Cooling and heating water

• Drinking water

• Broad range of refined hydrocarbons

• Potable water

• De-ionized and demineralized water

• Sanitary flow rate measurements

• Purified water

S 120 Oil Vapor Sensor

The new oil vapor sensor S 120 monitors oil contents of compressed air and gases permanently or for spot checks when used as portable unit in conjunction with S 551. The simple installation and the outstanding performance makes S 120 the ideal choice when oil vapor content needs to be measured and monitored.

Oil free compressed air is not an easy task to be achieved. Monitoring is a must in many industries and applications to avoid contaminations in products and risks for health of humans. S 120 makes this monitoring task affordable and reliable.

For best accuracy and long term stability, the sensor applies an automatic calibration. Sensor contaminations and sensor life time are monitored and will be indicated to the user. An over range detection will remove the sampling air from the sensor to protect it against contamination.

Application

• Medical air

• Pharmaceuticals

• Breathable air

• Marine air

• Food and beverage

• Medical engineering

• High speed trains

• Semiconductor fabs

• Conveyance of hygroscopic food

• High tech processes

• Electronics industry

Features

• Measures oil vapor contents in compressed air and other gases

• Can be used for permanent or in portable applications

• Measures down to 0.003 mg/m³

• Easy connection through sampling hose and quick connect

• Output signals: – 4 … 20 mA

– RS-485, Modbus/RTU

– Relay switch (NO)

• PID sensor for highest accuracy

• Service and Alarm indication through LED

• Connectable to SUTO displays and data loggers as well as third parties displays and control units

• Integrated 5” touch screen and data logger (option)

ติดต่อเรา

บริษัท ก้าวหน้า อินดัสทรีส์ แอนด์ เอ็นจิเนียริ่ง จำกัด

55/17 หมู่ 4 ต. บึงคำพร้อย อ. ลำลูกกา จ.ปทุมธานี 12150

02-159-9861-4

02-159-9860

info@kaowna.co.th

Line ID : @kaowna

ติดตามข่าวสาร

Copyright © 2016 by Kaowna Industry & Engineering Co.,Ltd. – All Rights Reserved