HHL Series Heatless Desiccant Air Dryer

Introduction

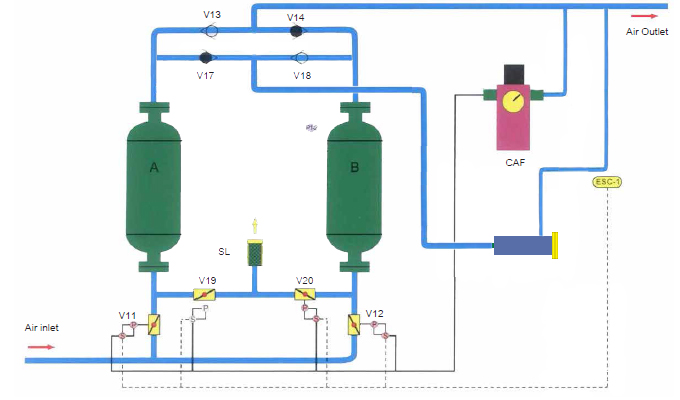

Heatless desiccant air dryer uses to identical vessel filled with desiccant. As wet air flows through one vessel, a portion of dry discharged air is diverted through the second vessel at close to atmospheric pressure, reactivating its desiccant. The moisture-laden purge air is vented to atmosphere. Some time later, air flow through the vessel is reversed.

System flowchart

Main Compenents

• PLC Controller to ensure righ reliability

• High quality pneumatic butterfly valve.

• Clamp type check valves provide tight shut-off and durability

• Angle seat valve for 0.7-13 m3/min

• Low breakdown rate of 2 way and 5 portsolenoid valve

• Extra filled quality activated alumina which has large adsorption capacity and good performance

Standard Working Conditions

• Working pressure 7-10 bar

• inlet temperature ≤ 45 ๐C

• Ambient temperature ≤ 45 ๐C

• Dew point ≤ -40 ๐C

• Purgeloss ≤ 14.5%

• Inlet oil content ≤ 0.1 ppm (w)

• Power supply 220 V/1PH/50Hz

• Desiccant Activated alumina

• Switch time 5-10 min

Options

• De point as low as – 70ºC

• Mounted air filters

• Dew point transduser

• PLC controller

• Different inlet / out connection

• Higher protection grade up to Lp65

• Molecular sieve + activated alumina

• Customized dimension for container shipment

• Stainless steel pipes lines and fittings

• Stainless steel pressure vessel

• ASME certificated pressure vessel

• Anticorrosion paint

Specifications