Screw Air Compressor หรือ Rotary Screw Air Compressor – เครื่องอัดอากาศแบบโรตารี่หรือแบบหมุน

เครื่องอัดอากาศหรือเครื่องปั๊มลมแบบนี้อัดอากาศเนื่องมาจากการเคลื่อนที่ผลักดันของโรเตอร์ในลักษณะแทนที่อากาศ อัตราการไหลสมํ่าเสมอ ค่าความดันค่อนข้างต่ำ โรเตอร์หมุนด้วยความเร็วสูงจึงมีอัตราการสึกหรอค่อนข้างสูง แบ่งประเภทออกเป็น

1. Sliding Vane Compressor มีใบนำร่องหรือใบกวาด (Vane) ทำหน้าที่กวาดและอัดอากาศให้มีปริมาตรเล็กลง

2. Liquid Piston Compressor ภายในจะมีของเหลวเป็นสารทำงานทำหน้าที่คล้ายลูกสูบ เพื่ออัดอากาศให้มีความดันสูงขึ้น

3. Two-impeller straight compressor มีอุปกรณ์คล้ายลอน (Lobe) 2 ชิ้น หมุนด้วยความเร็วที่สัมพันธ์กันเพื่ออัดอากาศไปใช้งาน ระบบนี้ได้อากาศความดันต่ำ

4. Helical or spiral lobe compressor ประกอบด้วยโรเตอร์หมุนภายในเรือนเครื่องอัดอากาศ 2 ตัว ตัวหนึ่งเป็นตัวผู้ อีกตัวหนึ่งเป็นตัวเมีย ทำหน้าที่คล้ายกระบอกสูบแต่ได้อากาศอัดที่ไหลอย่างต่อเนื่อง

Handal – Rotary Screw Air Compressor (HDS Series) – German Technology

HANDAL has been successfully manufacturing innovative products for diverse applications. Handal partner with customers across the globe in unique ways which transcend the ordinary company-customer interaction by providing solutions services and support long after product delivery, by exploring customer needs and applications.

HANDAL develops customer-engineered products which in turn helps the customer build better end-products, boost performance and command better markets, The HDS range of products is one among them. The HDS rang of rotary screw air compressor is offered with advance features that ensure high levels of reliability, effciency and economy.

Built and tested to HANDAL stringent manufacturing standards, the compressor is designed to perform in the most demanding conditions.

Feature the set HDS Series apart

- Energy-efficient

- High ambient compatibility

- robust construction with reliability built into every component

- High levels of safety

- Low life-cycle cost

Features and Benefits

- Inlet Filter – Efficient heavy inlet filter to ensure the quality of inlet air and safety of the airend, improved the life greatly.

- Efficient Air-Fluid Separation System – A high efficiency air-fluid separation system reduces compressor fluid carry over to less than 3 ppm. Low pressure drop air-fluid separation system reduces power consumption.

- High efficiency oil filter – Prevent impurities not go into the rotor and bearings, so that the air end components can be kept in good lubrication condition.

- Premium air end air compressor – HANDAL Premium efficiency compressors deliver reliability through our unique airends, reknowned for trouble-free operation and low energy consumption. efficiency and durability through low compression ratio in each stage. The air-end is originaly from germany with german technology and quality.

- Inherent Leak-Free Design – By using SAE O-ring fittings on most connections, we have significantly reduced potential leakage problems associated with conventional threaded connections.

- High efficiency direct coupling driven – Handal direct drive coupling type, high efficiency transmission, no energy loss. The revolution of motor is the revolution of airend, hence the efficiency is high.

- Heavy duty foot cum flanged motor – The heavy duty TEFC/IP54 foot cum flanged motor with reserve power fluctuations. High efficiency motors are more energy-efficient which help reducing power costs. Operating within power capabilities, it provides energy saving power costs.

- Intake Valve System – The New Generation capacity Control system integrated with blow down valve is installed at the compressor inlet. intake valve optimally controls the compressor capacity during startup, reducing the no – load power.

- Electricity Board – Main electrical components used in the world famous brand, greatly improve the service life.

- Control Panel – Control system, easy to operate unattended for 24 hours at work automatically.

System HDS Series

Intelligent controller – give you total control

- Monitor multiple machines built in sequencing of up to 8 machines.

- Install the optional integrated compressor controller and get simple, central control to reduce system pressure and energy consumption in installation of up to 20 compressors.

- HANDAL can monitor your compressor via the internet-based monitoring system that eliminates unnecessary service visits throung remote diagnosis

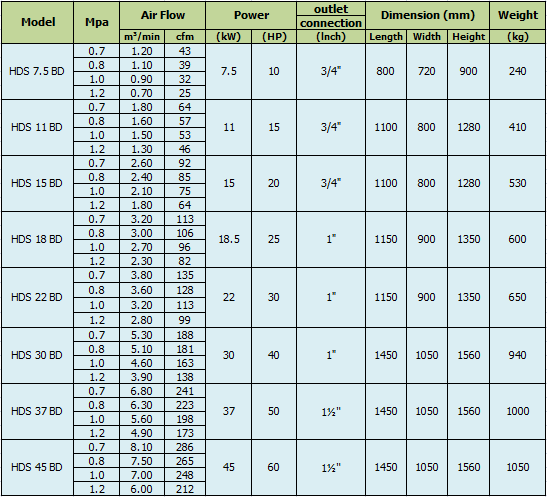

Belt Driven Series – เครื่องอัดลมแบบใช้สายพาน

- Genuine belt to meet the demands of heavy-duty, long life and high reliability.

- Convenient belt tensioning device makes the maintenance easy, and the transmission high-efficiency is ensured.

- Provide the flexibility for the customers to easily modify the working pressure if a change becomes necessary.

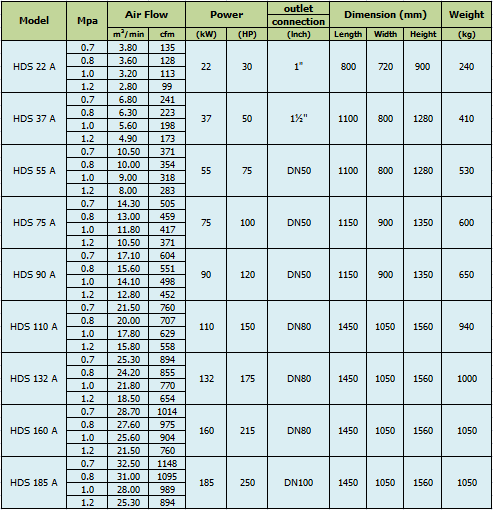

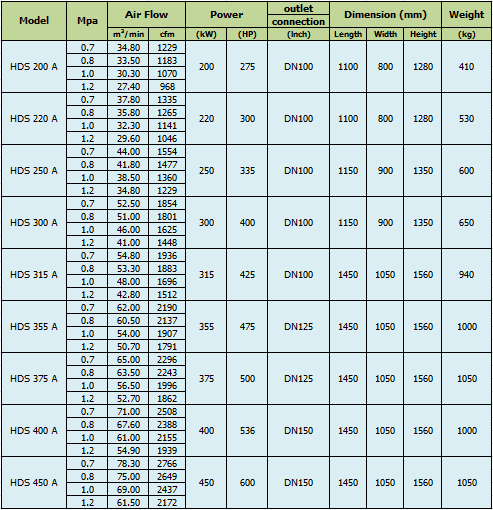

Direct Driven Series – เครื่องอัดลมแบบมอเตอร์

- The motor drives rotor directly through the flexible coupling and gear. This reduces the transmission consumption.

- Transmission efficiency is higher than belt driven type.

- Provide the flexibility for the customers to easily modify the working pressure if a change becomes necessary.

HDS-VSD Series : Ultimate Energy Saver

Advance inverter technology, integrated with the compressor with sophisticated vector control technology, HDS-VSD Series Compressor has unparalleled advantages.

- Superior technology platform, the motor input power factor up to 0.92.

- High-efficiency transformation of DC/AC inverter, reduces its energy consumption and improves the reliability, noise and unwanted harmonic are suppressed at the lowest possible level.

- High – Power inverter module configuration with superior ability of overload.

- Optional DC reactor, effectively improves the input side’s power factor, eliminates high harmonics of the inverter, and reduces external conduction and radiation interference.

- High reliability and long life design, the converter can run even in the ambient temperatures up to 50 °c

- The high-tech Elektronikon® graphic controller’s monitoring features include : warning indications, maintenance scheduling and an online visualization of your machines conditions.

Advanced Elektronikon® graphic controller

Advanced remote control, monitoring and communication systems ensure the compressor running with highest efficiency, reliability & lowest maintenance cost.

Generating compressed air can be accounted for more than 40% of a plant’s total electricity bill. Most production environments have a fluctuation (40-100%) air demand depending on the time of day, week, or even moths per year. While our users always select the compressor according to the maximum air demand.

With HDS-VSD technology, Handal Variable Speed Driven Technology mirror air usage automatically adjusts the motor speed depending on demand. When the user’s air demand is reduced, reduce the running speed, which help reducing the energy consumption.

HDS Belt Driven Series Technical Specification